CDI furler stud screw thread?

CDI furler stud screw thread?

I'm replacing the forestay. Anyone know what the stud thread is?

cheers

cheers

- Sumner

- Admiral

- Posts: 2375

- Joined: Sun Jan 04, 2009 3:20 pm

- Sailboat: MacGregor 26S

- Location: SE Utah

- Contact:

Re: CDI furler stud screw thread?

Do you have the old one or the turnbuckle? The thread could be 'right' or 'left' hand' . Get some nuts or bolts that are right hand and gently try and screw them in or on to what you have and see if they go. I'd start with 1/4 inch if the forestay is 1/8th inch. If you find the right dia. but they won't screw in or on then it is probably 'left hand' thread.

Can't you just send the old forestay to whoever is making up the new one?

Sum

===================================

Our MacGregor 26-S

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Mac-Venture Links

Can't you just send the old forestay to whoever is making up the new one?

Sum

===================================

Our MacGregor 26-S

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Mac-Venture Links

Re: CDI furler stud screw thread?

I'm making it up, and I only have metric stuff to hand (UK) . On reflection, didnt CDI use the original mac turnbuckle? 1/4 or 5/16? However, guess the answeer is to simply replace with a new complete metric turnbuckle.

FYI - mine had no top toggle and obviously had been bent over at some point, 4 strands had unravelled about 12inches. Whats the concesnsus on using flexible wire 7/19 over 1/19? Any disadvantage, given suffice breaking strain?

cheers

FYI - mine had no top toggle and obviously had been bent over at some point, 4 strands had unravelled about 12inches. Whats the concesnsus on using flexible wire 7/19 over 1/19? Any disadvantage, given suffice breaking strain?

cheers

- Sumner

- Admiral

- Posts: 2375

- Joined: Sun Jan 04, 2009 3:20 pm

- Sailboat: MacGregor 26S

- Location: SE Utah

- Contact:

Re: CDI furler stud screw thread?

I'd put a toggle on the top no matter which you used and I'd stay with the 1/19 as that seems to be the consensus on what is best to use. I'm probably wrong, but I think I read that if a person was restoring a very old boat and wanted to stay 'period perfect' then use the 7/19.133bhp wrote:I'm making it up, and I only have metric stuff to hand (UK) . On reflection, didnt CDI use the original mac turnbuckle? 1/4 or 5/16? However, guess the answeer is to simply replace with a new complete metric turnbuckle.

FYI - mine had no top toggle and obviously had been bent over at some point, 4 strands had unravelled about 12inches. Whats the concesnsus on using flexible wire 7/19 over 1/19? Any disadvantage, given suffice breaking strain?

cheers

Our S didn't have a furler when we bought her and had the forestay with the thimbles on the ends with a turnbuckle at the bottom. Adding the CDI only required having a forestay made up with a stud on the bottom that would screw into the old turnbuckle. I decided to go up to 5/32 and also replaced the original turnbuckle that was 1/4 with a 5/16. Since you can't safely put on a stud on the forestay at home I had the forestay made up by riggingonly.com for less than $50. Not sure if they ship overseas or not.

The info is here....

http://purplesagetradingpost.com/sumner ... ng-24.html

Besides the toggle at the top we put one below...

... the Johnson lever also. That might be a little redundant as the lever and the way it attaches to the drum creates in effect another toggle.

Good luck,

Sum

===================================

Our MacGregor 26-S

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Mac-Venture Links

- FinallySailing

- First Officer

- Posts: 281

- Joined: Fri Jul 02, 2010 2:37 am

- Sailboat: MacGregor 26S

- Location: The Sunny South East of England between Suffolk and Essex

Re: CDI furler stud screw thread?

I am at the process of rerigging my furler. I am using 3mm 1x19, previously there was 4mm but 1 think it was 7x7. Hopefully all will be finished tomorrow as long as I haven't forgotten how to use the swageless fittings. As Catigale pointed out in my previous thread, if you go for a higher strength wire you will have to put up a much higher tension (10% of the breaking strength) which then could be too much for the structures it is connected to.

http://www.macgregorsailors.com/forum/v ... 10&t=20258

http://www.macgregorsailors.com/forum/v ... 10&t=20258

- Sumner

- Admiral

- Posts: 2375

- Joined: Sun Jan 04, 2009 3:20 pm

- Sailboat: MacGregor 26S

- Location: SE Utah

- Contact:

Re: CDI furler stud screw thread?

Not to start a pi**ing match, but I talked to a technician at Loos & Co. today (800-321-5667) and he said there is no down side to running the same tension on a 5/32 forestay as you were running on the 1/8th. He said that with the larger wire diameter you can (if you want) run a higher tension as long as you don't run too much for the rest of the boat's structure as stated in the quote above. He went on to say that tension is tension and you run what is best for the boat within the limits of the wire you are running.FinallySailing wrote:... if you go for a higher strength wire you will have to put up a much higher tension (10% of the breaking strength) which then could be too much for the structures it is connected to....

http://loosnaples.com/how-to-use-90-91

With their chart on the link above they say you can run up to about 320 lb. on a 1/8 wire and I'll bet that most people on here are not running that with their boat. I thought I was close to that, but after buying the gauge I found I was down around 200 and that was pinning and then tightening the turnbuckle. I am now a little over 300 with the 5/32.

Unless you are pinning the forestay and then turning the turnbuckle you just can't get to around 300 in my opinion unless you have a Johnson Lever. Even now with the lever it is a hard pull with the mast stepping block and tackle to pin the forestay before locking the Johnson lever over.

I'm not saying that anyone has to run 300# as I'll bet Roger didn't count on people doing that. I will say that our shrouds and forestay are very tight now and I like it when I go forward and hold on to them,

Sum

===================================

Our MacGregor 26-S

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Mac-Venture Links

Re: CDI furler stud screw thread?

Thaks for advice all. I am assembling the hardware, and it seems you can buy a "per swage" at one or places I found on the net (UK based) In the meantime, I have rigged a second forstay and intend to use the old one till I get it sorted.

Out of interest, referring to using swageless fittings? can you get small enough diamater to slide up the luff?

Out of interest, referring to using swageless fittings? can you get small enough diamater to slide up the luff?

- FinallySailing

- First Officer

- Posts: 281

- Joined: Fri Jul 02, 2010 2:37 am

- Sailboat: MacGregor 26S

- Location: The Sunny South East of England between Suffolk and Essex

Re: CDI furler stud screw thread?

I think its is vital to have two headstays. Safety lies in redundance, esp. if us non-pros start playing around with vital bits of the rigging. I've now for the first time used swageless fittings, gone for Hi-Mod (by Petersen). I bought them from S3i, btw a good source for anything in 316 and £££ cheaper than my local chandler. Hi-Mod were the best priced I could find. And they do state that they are fully reusable, so for me as a rigging newbie I can redo everything without having to pay through the nose. The terminal does not fit through the inside of the luff extrusion, so you fix it once the wire is through it with the mast down. Plenty of space for it inside the furling drum, though. Now replacing my second headstay as well (order sent off today). Will be busy ...133bhp wrote:Thaks for advice all. I am assembling the hardware, and it seems you can buy a "per swage" at one or places I found on the net (UK based) In the meantime, I have rigged a second forstay and intend to use the old one till I get it sorted.

Out of interest, referring to using swageless fittings? can you get small enough diamater to slide up the luff?

- DaveB

- Admiral

- Posts: 2543

- Joined: Mon Jan 07, 2008 2:34 pm

- Sailboat: MacGregor 26X

- Location: Cape Coral, Florida,1997 Mac. X, 2013 Merc.50hp Big Foot, sold 9/10/15

Re: CDI furler stud screw thread?

Sumner,

Adding the 5/32nd headstay will add less flexing on head sail. Adding a Johnson quick release is also very good without useing a gin pole. The Johnson lever requires those who have stock CDI, Headsail to put a higher support Y in mast for the extra length of forestay.

The 5/32 forestay does work great and with the Johnson release lever will give all standing rigging a much tighter tension, without gin pole.

It is also wise to put the Johnson on backstay.

As always Sum, you always have great suportive info and for one love your mods and ventures.

Dave

Adding the 5/32nd headstay will add less flexing on head sail. Adding a Johnson quick release is also very good without useing a gin pole. The Johnson lever requires those who have stock CDI, Headsail to put a higher support Y in mast for the extra length of forestay.

The 5/32 forestay does work great and with the Johnson release lever will give all standing rigging a much tighter tension, without gin pole.

It is also wise to put the Johnson on backstay.

As always Sum, you always have great suportive info and for one love your mods and ventures.

Dave

Sumner wrote:Not to start a pi**ing match, but I talked to a technician at Loos & Co. today (800-321-5667) and he said there is no down side to running the same tension on a 5/32 forestay as you were running on the 1/8th. He said that with the larger wire diameter you can (if you want) run a higher tension as long as you don't run too much for the rest of the boat's structure as stated in the quote above. He went on to say that tension is tension and you run what is best for the boat within the limits of the wire you are running.FinallySailing wrote:... if you go for a higher strength wire you will have to put up a much higher tension (10% of the breaking strength) which then could be too much for the structures it is connected to....

http://loosnaples.com/how-to-use-90-91

With their chart on the link above they say you can run up to about 320 lb. on a 1/8 wire and I'll bet that most people on here are not running that with their boat. I thought I was close to that, but after buying the gauge I found I was down around 200 and that was pinning and then tightening the turnbuckle. I am now a little over 300 with the 5/32.

Unless you are pinning the forestay and then turning the turnbuckle you just can't get to around 300 in my opinion unless you have a Johnson Lever. Even now with the lever it is a hard pull with the mast stepping block and tackle to pin the forestay before locking the Johnson lever over.

I'm not saying that anyone has to run 300# as I'll bet Roger didn't count on people doing that. I will say that our shrouds and forestay are very tight now and I like it when I go forward and hold on to them,

Sum

===================================

Our MacGregor 26-S

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Mac-Venture Links

Re: CDI furler stud screw thread?

FinallySailing wrote:I think its is vital to have two headstays. Safety lies in redundance, esp. if us non-pros start playing around with vital bits of the rigging. I've now for the first time used swageless fittings, gone for Hi-Mod (by Petersen). I bought them from S3i, btw a good source for anything in 316 and £££ cheaper than my local chandler. Hi-Mod were the best priced I could find. And they do state that they are fully reusable, so for me as a rigging newbie I can redo everything without having to pay through the nose. The terminal does not fit through the inside of the luff extrusion, so you fix it once the wire is through it with the mast down. Plenty of space for it inside the furling drum, though. Now replacing my second headstay as well (order sent off today). Will be busy ...133bhp wrote:Thaks for advice all. I am assembling the hardware, and it seems you can buy a "per swage" at one or places I found on the net (UK based) In the meantime, I have rigged a second forstay and intend to use the old one till I get it sorted.

Out of interest, referring to using swageless fittings? can you get small enough diamater to slide up the luff?

yep, you'd think "ROG" would have added one, even an old bit old rope!, espcially for the target audience that assumed one OEM was enough! or did till started reading about dropped masts.

I noticed S31 too. But need pics of your swageless setup and may well copy

- FinallySailing

- First Officer

- Posts: 281

- Joined: Fri Jul 02, 2010 2:37 am

- Sailboat: MacGregor 26S

- Location: The Sunny South East of England between Suffolk and Essex

Re: CDI furler stud screw thread?

I am off all next week, will be going up North for a few days to see how the renovation of the money pit is progressing. I will post some pictures of my setup next time I'm in Burnham. PM me if I haven't managed to do so by 11/6 ...133bhp wrote: But need pics of your swageless setup and may well copy

- FinallySailing

- First Officer

- Posts: 281

- Joined: Fri Jul 02, 2010 2:37 am

- Sailboat: MacGregor 26S

- Location: The Sunny South East of England between Suffolk and Essex

Re: CDI furler stud screw thread?

Ok, as promised some pictures and info on the swageless fittings.

I've used 3mm 1x19 316 grade stainless steel wire and the 3mm swageless fittings by Petersen (Hi-Mod). I've never swaged nor have I done any standing rigging before. I have no access to swaging tools. I choose Hi-Mod because a) they were the best priced b)they are made in this country and are not some cheap Chinese import c) they at least in theory are 100 % re-usable d) they do not need sealing with silicone e) because I read some good reviews in other sailing forums and f) ... probably the most important ... they actually make all the fittings that I needed for 3 mm wire.

On the mast end my headstay was fixed with a bolt through a thimble. CDI (and some on this forum) do not recommend this. I've now changed this as per the CDI manual to a toggle fitting.

The other end of the stay terminates in an eye fitting. This will connect on to the fork of the bottle screw inside my furling cup.

The swageless terminals themselves do not fit through the luff extrusion. So I first connected one terminal onto the wire, pushed the wire through the luff extrusion and then fixed the other terminal. The furling drum itself then will be fixed with another toggle.

I've used 3mm 1x19 316 grade stainless steel wire and the 3mm swageless fittings by Petersen (Hi-Mod). I've never swaged nor have I done any standing rigging before. I have no access to swaging tools. I choose Hi-Mod because a) they were the best priced b)they are made in this country and are not some cheap Chinese import c) they at least in theory are 100 % re-usable d) they do not need sealing with silicone e) because I read some good reviews in other sailing forums and f) ... probably the most important ... they actually make all the fittings that I needed for 3 mm wire.

On the mast end my headstay was fixed with a bolt through a thimble. CDI (and some on this forum) do not recommend this. I've now changed this as per the CDI manual to a toggle fitting.

The other end of the stay terminates in an eye fitting. This will connect on to the fork of the bottle screw inside my furling cup.

The swageless terminals themselves do not fit through the luff extrusion. So I first connected one terminal onto the wire, pushed the wire through the luff extrusion and then fixed the other terminal. The furling drum itself then will be fixed with another toggle.

- FinallySailing

- First Officer

- Posts: 281

- Joined: Fri Jul 02, 2010 2:37 am

- Sailboat: MacGregor 26S

- Location: The Sunny South East of England between Suffolk and Essex

Re: CDI furler stud screw thread?

Now about the swageless fittings:

I've followed basically the instructions by Hi-Mod on the Hayn link : http://www.youtube.com/watch?v=sb4swA3xguQ

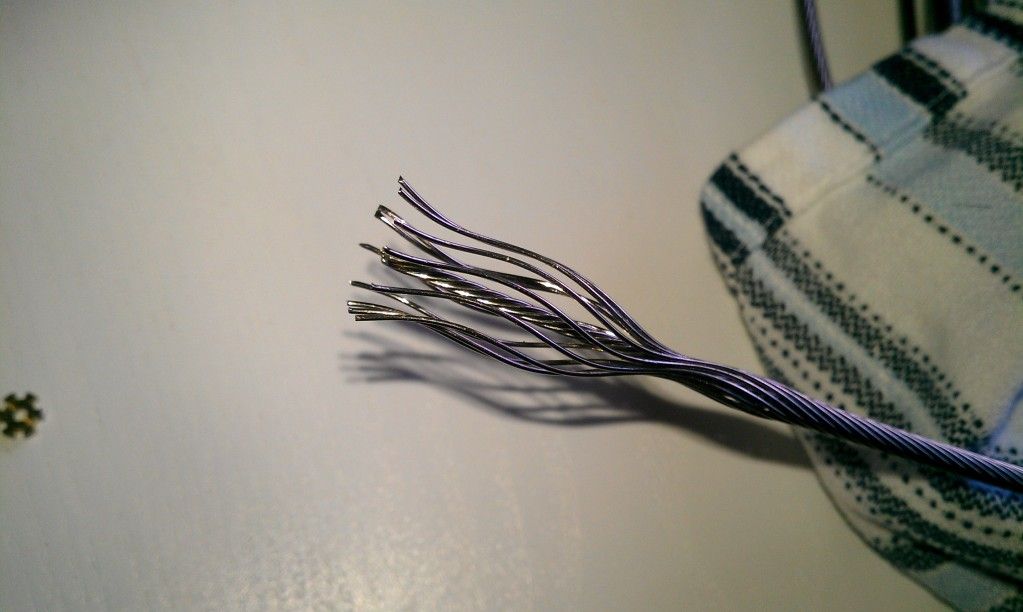

Now, my wire is much smaller and my fingers felt sooo much more like sausages when I fitted these. Look at how small the cone and crown are here :

Took me a while to get the idea ... The pictures I've got here are btw from when I started assembling my second forestay at home.

... The pictures I've got here are btw from when I started assembling my second forestay at home.

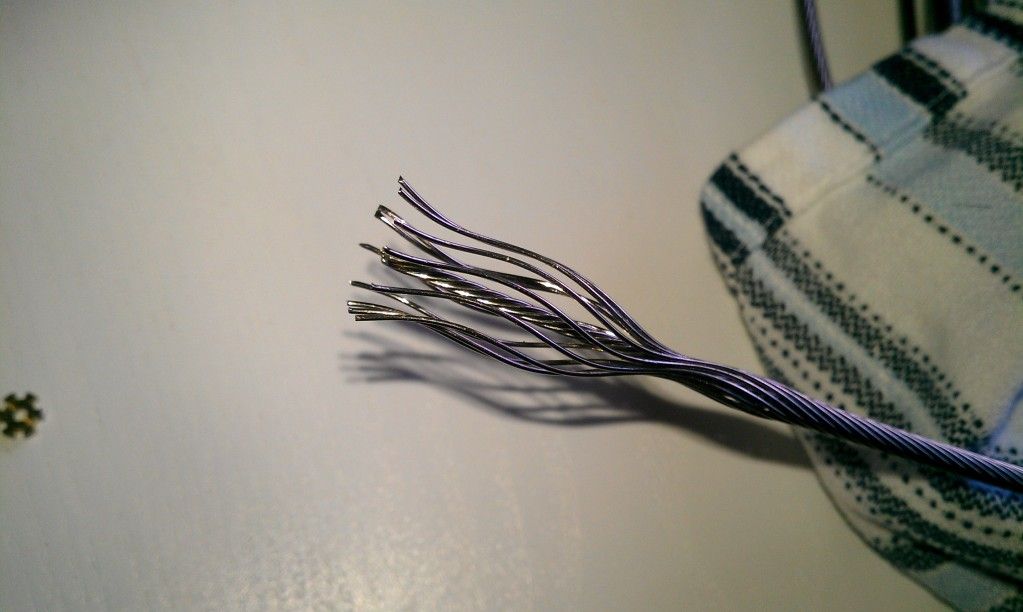

So you untwist the strands of the wire and the fix the cone and crown over it:

Close the fitting, twist the strands together at the same time. You will then have to fiddle a pair of strands into each of the notches of the crown - ehm did I mention this was very fiddly

Close everything together, open it up and when you are 100 % sure everything is ok put some thread lock onto the thread of the fitting and NOT inside the fitting (cause you won't be able to undo it ... taught myself a lesson there). Petersen states not to overtighten the fittings.

The end product looks good, can be opened up, inspected and re-used.

I've followed basically the instructions by Hi-Mod on the Hayn link : http://www.youtube.com/watch?v=sb4swA3xguQ

Now, my wire is much smaller and my fingers felt sooo much more like sausages when I fitted these. Look at how small the cone and crown are here :

Took me a while to get the idea

So you untwist the strands of the wire and the fix the cone and crown over it:

Close the fitting, twist the strands together at the same time. You will then have to fiddle a pair of strands into each of the notches of the crown - ehm did I mention this was very fiddly

Close everything together, open it up and when you are 100 % sure everything is ok put some thread lock onto the thread of the fitting and NOT inside the fitting (cause you won't be able to undo it ... taught myself a lesson there). Petersen states not to overtighten the fittings.

The end product looks good, can be opened up, inspected and re-used.

- DaveB

- Admiral

- Posts: 2543

- Joined: Mon Jan 07, 2008 2:34 pm

- Sailboat: MacGregor 26X

- Location: Cape Coral, Florida,1997 Mac. X, 2013 Merc.50hp Big Foot, sold 9/10/15

Re: CDI furler stud screw thread?

When I went on my 3 year cruise from Cape Cod thru the Carribean on my Alberg 35. I upgraded all standing rigging . one wire size greater, Stay-Lock connections that is much like yours or Norseman. Rail down 35-80 degrees in 40 ft. seas for 3 days proves there strength.

Best advantage is you can change fittings at sea. (I didn't have to)

Your toggle connection at head looks good but a rotating pin would be much better, have the same at lower.(The pin and Eye will wear if you are a down to the Rail type)

Dave

Best advantage is you can change fittings at sea. (I didn't have to)

Your toggle connection at head looks good but a rotating pin would be much better, have the same at lower.(The pin and Eye will wear if you are a down to the Rail type)

Dave

FinallySailing wrote:Ok, as promised some pictures and info on the swageless fittings.

I've used 3mm 1x19 316 grade stainless steel wire and the 3mm swageless fittings by Petersen (Hi-Mod). I've never swaged nor have I done any standing rigging before. I have no access to swaging tools. I choose Hi-Mod because a) they were the best priced b)they are made in this country and are not some cheap Chinese import c) they at least in theory are 100 % re-usable d) they do not need sealing with silicone e) because I read some good reviews in other sailing forums and f) ... probably the most important ... they actually make all the fittings that I needed for 3 mm wire.

On the mast end my headstay was fixed with a bolt through a thimble. CDI (and some on this forum) do not recommend this. I've now changed this as per the CDI manual to a toggle fitting.

The other end of the stay terminates in an eye fitting. This will connect on to the fork of the bottle screw inside my furling cup.

The swageless terminals themselves do not fit through the luff extrusion. So I first connected one terminal onto the wire, pushed the wire through the luff extrusion and then fixed the other terminal. The furling drum itself then will be fixed with another toggle.

- FinallySailing

- First Officer

- Posts: 281

- Joined: Fri Jul 02, 2010 2:37 am

- Sailboat: MacGregor 26S

- Location: The Sunny South East of England between Suffolk and Essex

Re: CDI furler stud screw thread?

Thanks Dave, I'll see to that !DaveB wrote:Your toggle connection at head looks good but a rotating pin would be much better, have the same at lower.(The pin and Eye will wear if you are a down to the Rail type)