I don't know, under most conditions, how fast you'd have to react with the manual system, in the event of a powered mode fail. Some risk would have to be taken, probably similar to a malfunction with your car windows or steering during an 'event'. You'd still have the MacGregor power rescue backup option available. We do always wonder if the day ever comes when we'll bust the damn thing off on a rock!

A manual override is absolutely desirable but I wouldn't bother with more than a replacement drill motor & chuck. If the angle drive shredded, or the jacksrew snapped - why is that different than a dagger-board breaking or a rudder saying sayonara? Overall, the system is still only operated very intermittently and could be over engineered to exceed the capabilities of a rope .

R.

Twin Asymmetrical daggerboards

- Crikey

- Admiral

- Posts: 1833

- Joined: Sun Apr 17, 2011 12:43 pm

- Sailboat: MacGregor 26M

- Location: Washago, Muskoka, Ontario, Canada, Earth, Singularity.Suzuki DF60A. Boat name: Crikey!

Re: Twin Asymmetrical daggerboards

The size of any screw dimension would be limited by the width of the free space inside the dagger-board. Probably an inch. For this reason I'm thinking the only material that would have the required strength and stiffness, would be stainless. It seems there's lots of these around for the food industry, and one I've seen can be had with SS a circulating ball nut. Err... did I say that!

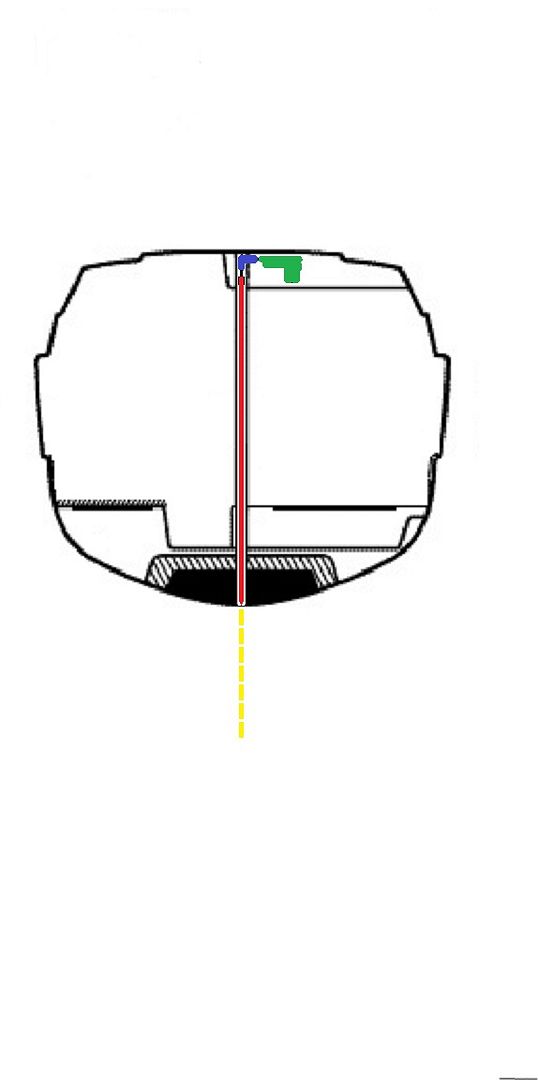

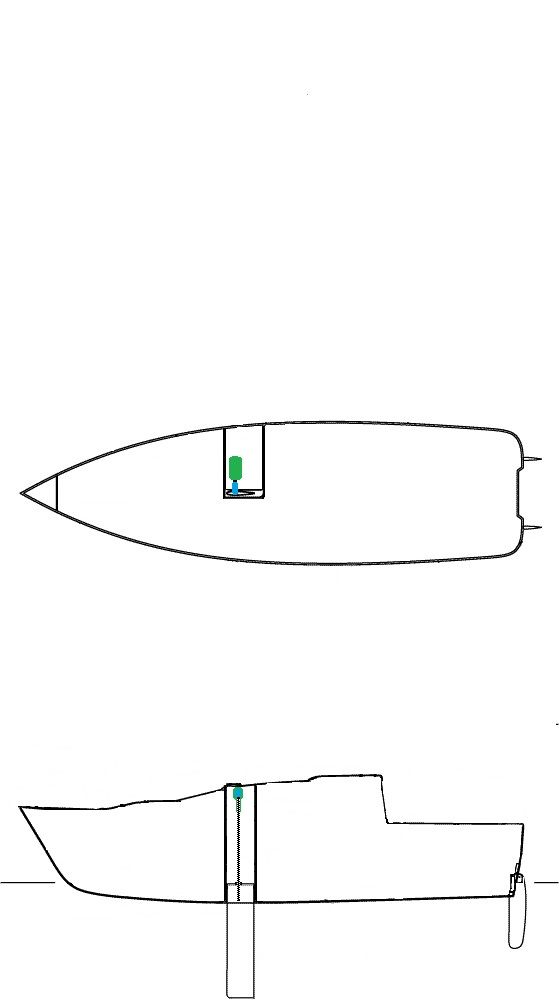

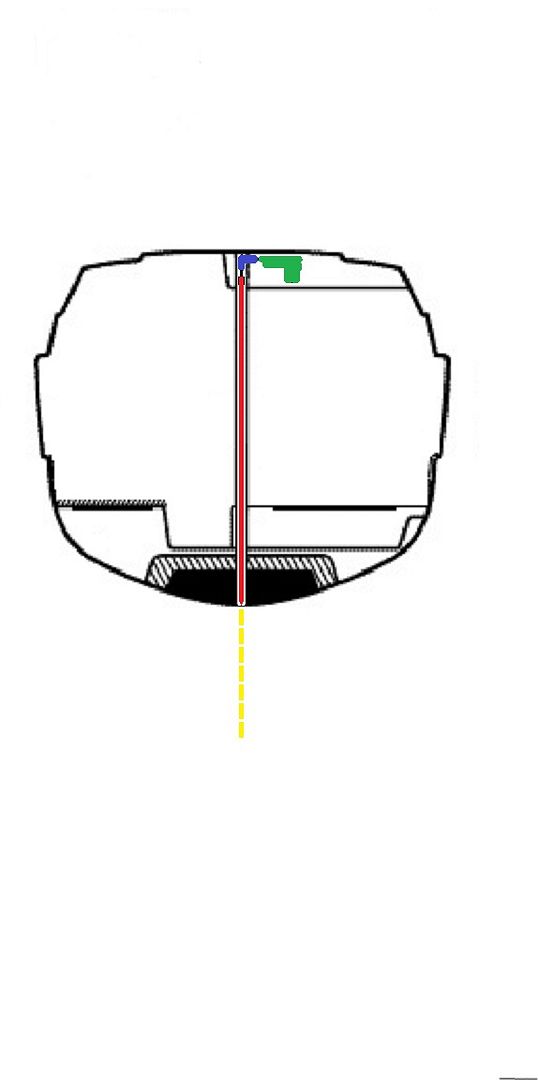

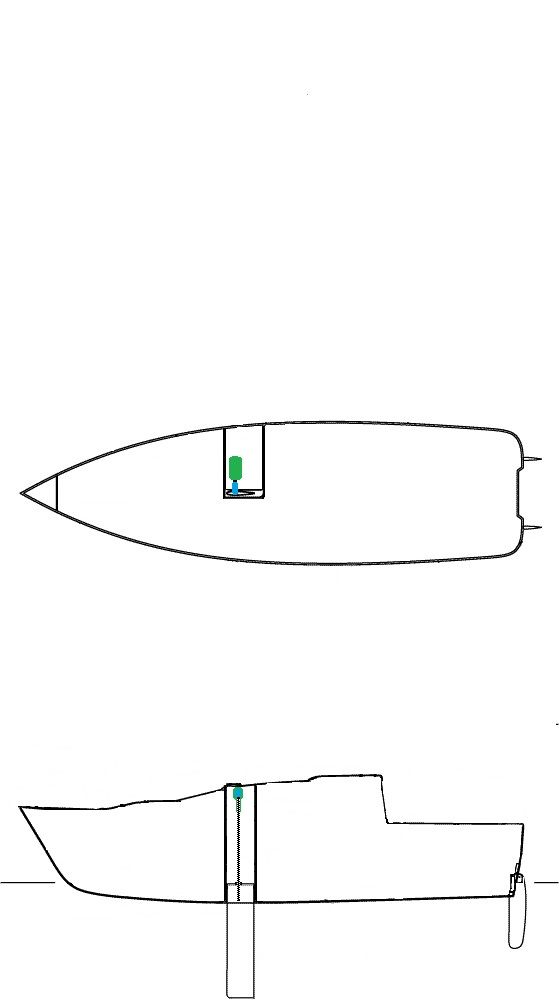

Here's a couple of rough in's.

R

Here's a couple of rough in's.

R

Re: Twin Asymmetrical daggerboards

Neat thread and very informative.

Me, I would approach this in a different way. Build a dagger board with a deformable skin. Deformation to shape the aero foil as needed. Deformation could be by a cam at the top of the board. The cam could be winched or motorised.

Me, I would approach this in a different way. Build a dagger board with a deformable skin. Deformation to shape the aero foil as needed. Deformation could be by a cam at the top of the board. The cam could be winched or motorised.

- finding41

- Engineer

- Posts: 154

- Joined: Mon Dec 19, 2011 12:59 pm

- Sailboat: MacGregor 26D

- Location: LITTLE CURRENT ONT.

- Contact:

Re: Twin Asymmetrical daggerboards

I like your thinking Jim.

I have been thinking along the same lines. Have a solid leading edge that's shape is rounded going back to a end about 1/2" wide. In between have some sort of flexible membrane skin with a cog that turns and sits in 3 positions. One specific for each tack and one normal shape.

Man I wish I had CAD.

Oh well... graph paper works too.

I have been thinking along the same lines. Have a solid leading edge that's shape is rounded going back to a end about 1/2" wide. In between have some sort of flexible membrane skin with a cog that turns and sits in 3 positions. One specific for each tack and one normal shape.

Man I wish I had CAD.

Oh well... graph paper works too.